led by Ing. Dr. Mathias Mehofer, email: mathias.mehofer@univie.ac.at

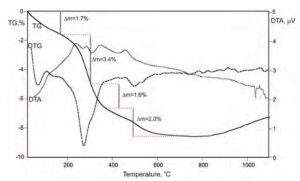

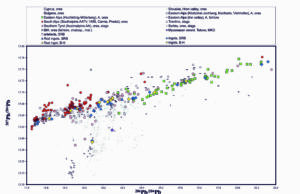

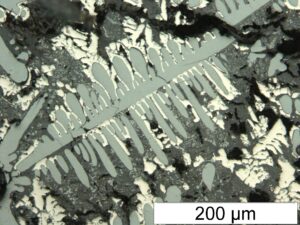

The Materials Science laboratory of VIAS (University Vienna) was established in 1998 to conduct in-depth archaeometallurgical studies on prehistoric and historic metallurgy. In an interdisciplinary approach, various methods such as metallography, surface analyses, SEM-EDS, 3D X-ray tomography, DTA-TG(DTG), geochemistry and isotope research are combined to access cultural-historical questions. Initially set up as a metallographic laboratory, it was continuously expanded over the years. For example, a large-chamber scanning electron microscope and a handheld XRF device were acquired to broaden the analytical scope.

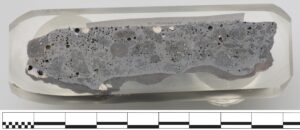

The laboratory is well equipped for the analysis of metals and other remains from the metal production processes. Additionally, the laboratory holds an extensive reference collection of materials connected to ancient metallurgy (approx. 400 samples). This includes representative samples of metal artifacts, metallurgical by-products such as slags and ores, as well as technical ceramics, including crucibles, tuyères, and furnace linings.

Instrumentation and Equipment

-SEM-EDS: Zeiss EVO 60 XVP, environmental SEM with low preasure mode (specimen chamber diameter 400 mm, height 240 mm); analytical unit: detector: Ultim MAX 170, AZtec, Oxford instruments, Sputter unit (carbon)

– pXRF: Handheld X-Ray Fluorescence Analyzer, Bruker Tracer 5g

– Optical microscope: Olympus BX 51, reflected light microscope, Olympus software

– Sample preparation: Struers Tegramin 30: automatic grinding – polishing machine

Imptech 10 DVT Grinder Polisher: automatic grinding – polishing machine

– Hardness testing: Vickers micro hardness testing device

– Mounting equipment for resin block samples

– Etchants for copper-based, iron and silver samples (Ferric Chloride (FeCl₃), Ammonium Persulfate ((NH₄)₂S₂O₈), Nital, Oberhoffer´s reagent, dilute nitric acid etc.)

– Experimental Archaeometallurgy equipment (pyrometer, sensors)

– Dremel tools for sample extraction

– Reference books for metallography, material science and archaeometallurgy

Certified reference materials (CRM, selection)

Numerous CRMs are available, this comprises certified standards comparable to prehistoric and medieval alloys (e.g tin-bronze, quaternary Cu-Sn-Pb-Zn alloys, brass) as well as slags: CCU-1e, BAM-M376a, BAM-M397, BAM-374 (ERM-EB374), BAM-375 (ERM-EB375), BAM-377 (ERM-EB377), BCR-691, MBH-31X 7835.5 A-C (batch A), MBH-31X CZ114 A-C, MBH-31X 7835.8 A3, MBH-31X TB 4 A4, MBH-32X Sn7 A, MBH-32X LB 17 A1, MBH-36X CuAs 3, MBH-36X CuAs 4, MBH-36X SP2 A-C (batch A), MBH-37X 218 B-C (CHARM-set)

Research Projects (selection)

- Hallmetals-Materials science analyses on metals from the famous Iron Age cemetery of Hallstatt, Austria

- Materials science examinations of the medieval „Agnes“ candelabrum in the Klosterneuburg monastery, A

- Archaeometallurgical and mining archaeological studies on Bronze Age metallurgy in the Western Balkans (FWF project P 32095)

- Metal exchange networks and hoard biographies in Late Bronze Age Romania

- Archaeometallurgical analysis on the Holy Lance in the Treasury of the Kunsthistorisches Museum Wien

- Excavations at the medieval fortification of Neudegg, Lower Austria

- The early Hungarian warrior grave from Gnadendorf, Lower Austria

- Early medieval blacksmith’s graves in Central Europe

In case further research questions arise—such as provenance analyses of copper or gold using mass spectrometry—we collaborate with various research institutions, such as the CEZA Mannheim, the German Mining Museum in Bochum, or the Geochemistry Lab of the Austrian Academy of Sciences.

Video on Materials science at VIAS, University Vienna

RESEARCH FOCUS

The Materials Science laboratory of VIAS conducts intensive research in the field of archaeometric analysis of archaeological artefacts. The objective is to reconstruct and describe an entire technological chaîne opératoire (raw material – processing – finished product – reuse) as well as to document the changes and influences on archaeological/cultural heritage artefacts caused by the surrounding soil or deposition practices.

Technological analysis of the production and use of metal objects

The description, classification, and typology of archaeological artefacts form the basis for both the documentation and interpretation of archaeological contexts and for the reconstruction of prehistoric value and social systems. Metallurgical analyses and technological studies of metal artefacts — including the by-products and waste materials generated during their production (e.g., slag) — provide insights into material treatment processes and allow for the assessment of the quality of raw materials (e.g., alloy composition). Through detailed archaeometallurgical analyses, it is possible to gain knowledge of an artefact’s specific material properties, thereby enabling the identification of individual workshop traditions, production centres, and patterns of technological transfer. These techno-typological investigations not only advance our understanding of the craftsmanship and smithing techniques of a given era but also, in combination with historical sources, offer deeper insights into prehistoric societal structures.

Archaeometallurgical investigations of non-ferrous and precious metal objects

(in cooperation with the Department of Fine Metalworking)

Another research focus in the field of metallurgy is the non-destructive investigation of precious and non-ferrous metal objects using scanning electron microscopy (SEM-EDS) or a handheld XRF. Particular emphasis is placed on examining manufacturing techniques and determining the chemical composition (major and trace elements) of artefacts. The documentation of technological features enables the reconstruction and description of production processes for individual finds, as well as the grouping of objects based on techno-typological criteria. These groups may then be correlated with archaeological evaluations, allowing for the reconstruction of technological developments within specific historical periods.

Experimental Archaeology

In all these areas of research, experimental archaeology plays a crucial role. This methodological approach provides essential insights into the production and use of artefacts as well as into the formation of archaeological contexts. By conducting meticulously documented experiments, theoretical assumptions regarding an objects production process can be critically tested. Currently, various experimental series on iron smelting and processing, as well as on copper smelting and working, are being conducted. The material samples produced in these experiments serve as comparative references, enabling not only the typological but also the techno-typological classification and interpretation of archaeological finds. This approach fosters a more profound understanding and more accurate description of ancient technological processes.

Materials Science Laboratory

Materials Science Laboratory

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.